Features

Unique Multi-functional Body

The body of the Delta-CAP, identical to that of the Tetra-CAP, has many advantages: the three-way tipping system, but also the multiple possible combinations of side panels that make it possible to reach volumes from 4 to 26 m³ for the biggest model. The tipping trailer can also be fitted with extensions for silage and with an unloading auger driven by hydraulic motor.

Different hitching gears available

Thanks to its three-way tipping system, the Delta-CAP can be used alone or with a Tetra-CAP (with the same or a smaller capacity) hitched at the back. In this way, the transported volumes can significantly be increased.

Thanks to the weight transfer onto the eyelet of the Delta-CAP improving the grip of the tractor and to the carrier system connected to the tractor, the combined machine is very easy to pull on all types of ground.

Two 5025 Delta-CAP or Tetra-CAP models, hitched together to a standard tractor, exceed not 18. 75 m in length, (limit set in several European countries), but however offer volumes up to 38 m³.

Strong and Tight Bodies

Tipping trailers with drop sides are standard manufactured in the same special high tensile steel as the one used to manufacture road transport vehicles. It is the best guarantee of solidity for a relatively low weight. The bottom plate is 4 mm thick. The drop sides have a structure with closed profiled tubes, which allows to increase the resistance to pressure of the walls and give a fluid and modern design to the machine.

In order to ensure a longer life span, the chassis of the JOSKIN tipping trailers with drop sides, except the one of the Trans-EX, are completely hot dip galvanized.

The tipping trailers with drop sides are standard fitted with highly resistant synthetic rubber seals all around the body allowing a perfect tightness of the tipping trailer, even with small grains or products like rapeseed.

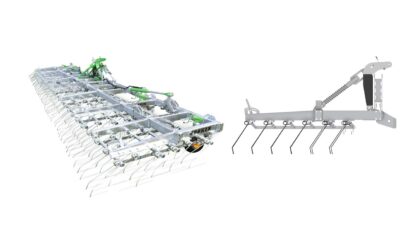

Modularity and Simplicity

JOSKIN tipping trailers with drop sides were developed to be as modular as possible. Many volumes and heights are available, which allows to reach higher loading volumes. The side panels can be demounted in order to have a bale trailer.

The handles to open the side panels were designed in such a way that they are easy to use. With their large length and the rubber at their end, they ensure an easy opening/closing.

Tipping Adapted to all Situations

In some difficult to reach places or in order to tip precisely, it can be useful to be able to tip on the sides of the trailer. It is the purpose of the “three-side tipping” option that allows to tip backwards, to the left or to the right. In this case, the tipping cylinder is fastened to an oscillating frame and the lateral tipping angle is limited by an end of stroke cable.

Safety and Comfort

JOSKIN tipping trailers with drop sides are all standard fitted with a rear yoke with complete connections for the lighting, braking system and tipping of a second trailer. The low center of gravity of the tipping trailers ensures a better stability and in this way an improved driving comfort both on the roads and in the fields.